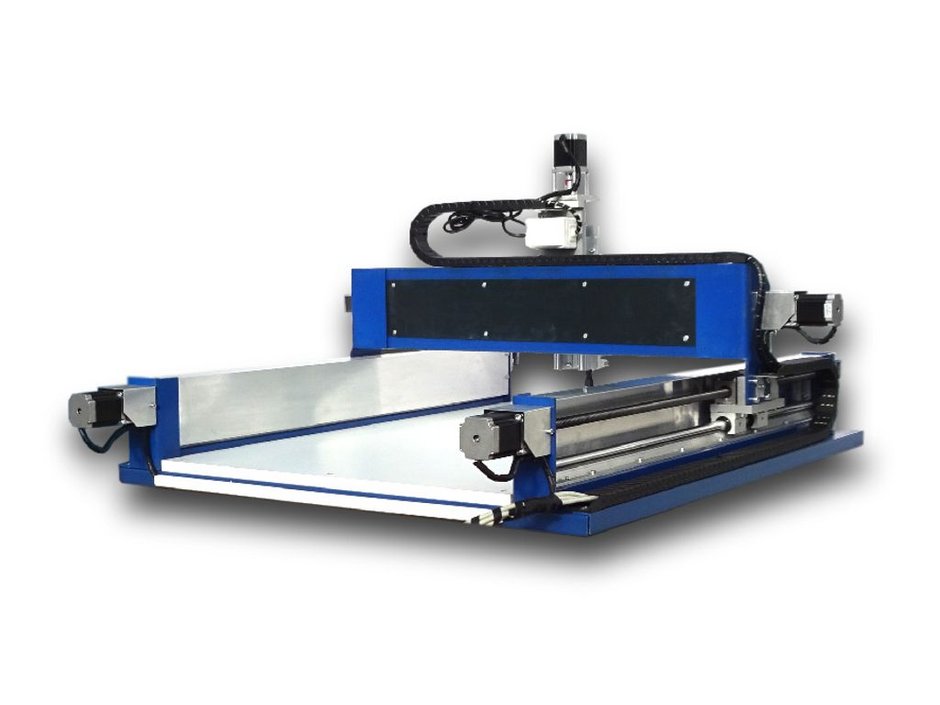

Gantry Mill Step490

STEP-490

The STEP-490 is the ideal solution for precise machining of large and flat workpieces. With its generous working area, it is perfectly suited for applications such as:

- PCB prototyping

- Engraving and labeling

- Front panel and enclosure machining

The machine stands out due to its high repeatability, user-friendly operation, and robust construction – making it perfect for professional use in electronics, model making, or custom small-series production.

Technical Specifications

| Number of CNC axes | 3 |

| Workarea | X=490, Y=310, Z=150 mm |

| Max. feed rate | 1500 mm/min |

| Size of work base | 710*x435 mm (* open work area, larger material can be used) |

| Overal size | approx. 900x800x760 mm |

| Weight | approx. 55kg |

| Milling motor | KRESS 800FME (800W, collets 8mm, 6mm+1/8") |

| Further | recirculating ball screw spindles, plain bearing guideways on hardened and polished steel arbors (X/Y Ø 20 mm, Z Ø20mm), 2-Amp stepper motors, reference switches |

| Controller | TCTCONT6 included |

| T-Slot table | optional, see accessories |

Gantry Mill STEP-1000

| Number of CNC axes | 3 |

| Workarea | X=850, Y=600, Z=160 mm |

| Max. feed rate | 1500 mm/min |

| Size of work base | 880*x1110 mm (* open work area, larger material can be used) |

| Overal size | approx. 1300x1100x600 mm |

| Weight | approx. 85kg |

| Milling motor | KRESS 800FME (800W, collets 8mm, 6mm+1/8") |

| Further | recirculating ball screw spindles, plain bearing guideways on hardened and polished steel arbors (X/Y Ø 20 mm, Z Ø20mm), 2-Amp stepper motors, reference switches |

| Controller | TCTCONT6 included |

| T-Slot table | optional, see accessories |