![[Translate to English:] UNIMAT CNC Varianten Übersichtsbild](/fileadmin/_processed_/8/9/csm_CNC-Ensemble_skaled_1104d8ec30.jpg)

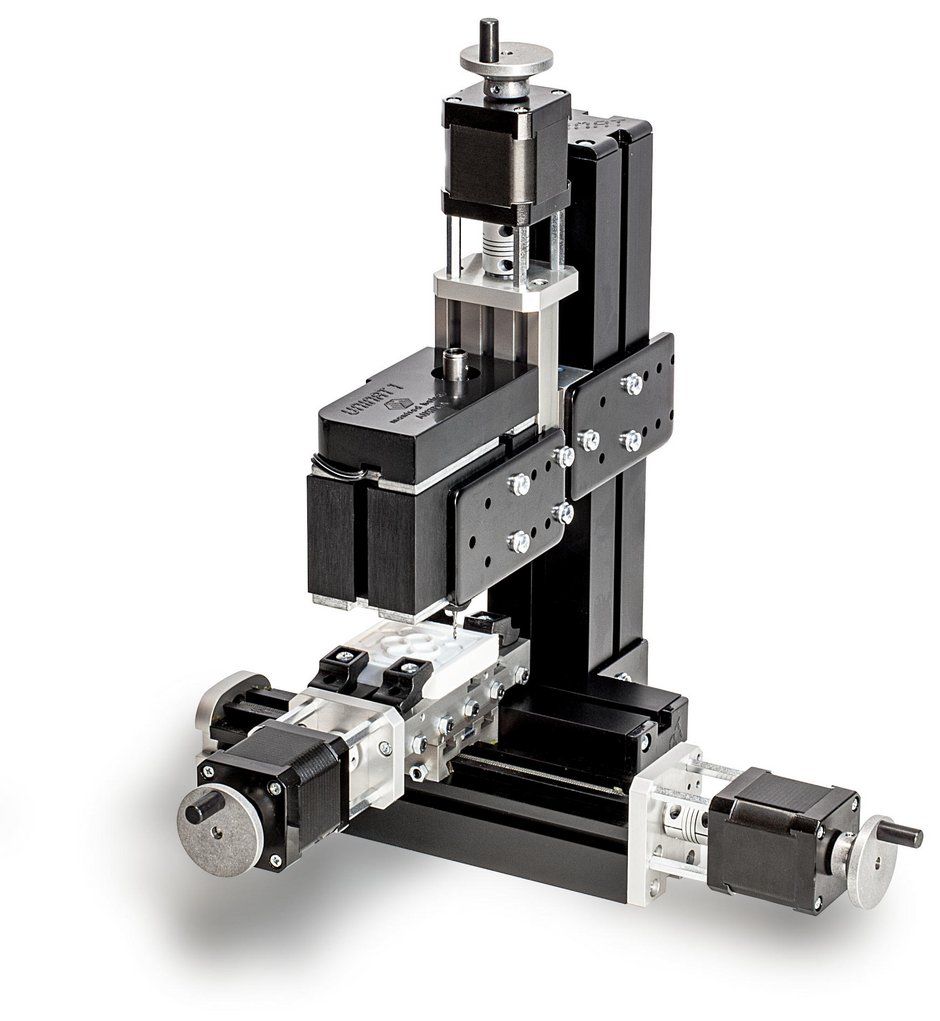

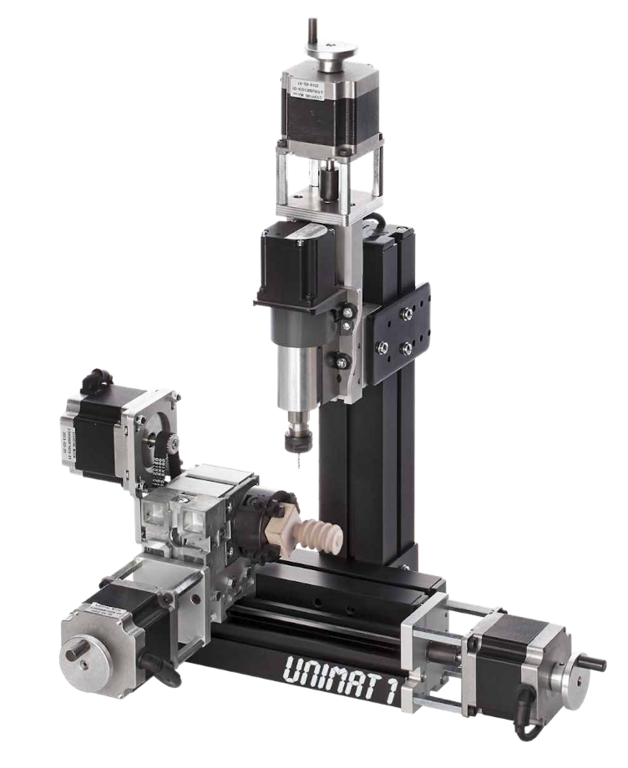

The UNIMAT CNC is a versatile, modular CNC system specifically designed for use in model making and prototyping. It allows for precise work in minimal space and offers a wide range of applications thanks to its modular construction.

🔧 Technical Highlights

- Modular design: Enables setup of various machine configurations, such as a CNC lathe, 3-axis and 4-axis milling machine, or hot wire cutter.

- Precision manufacturing: All components are produced on state-of-the-art CNC machines, ensuring maximum accuracy.

- Wide material compatibility: Suitable for processing wood, plastics, wax, as well as non-ferrous and soft metals.

- Compact dimensions: Ideal for workshops with limited space.

🛠️ Expansion Options

The UNIMAT CNC can be enhanced with optional accessories, including:

- Laser engraving module – for detailed engraving on wood, leather, and acrylic.

- 3D printer extension – build your own 3D printer for prototyping.

- Hot wire cutter – perfect for cutting foam and similar materials.

With the UNIMAT CNC, you get a reliable, flexible, and precise CNC system suitable for both beginners and advanced users.

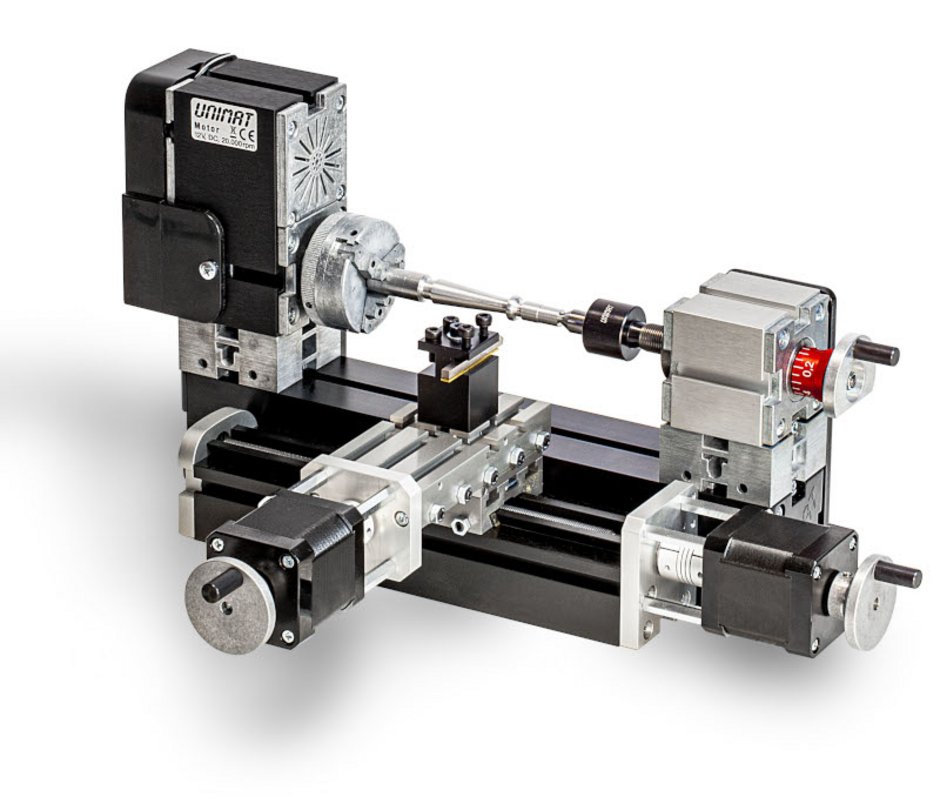

UNIMAT CNC Lathe

UNI-DREH

3-Jaw-Chuck, precision live centre, tool post and turning tool.

Machinable materials: wood, acrylics, wax, non-ferrous and soft metals.

| Drive | Steppers, 2 A, 1.8° | |

| Nubmer of CNC axes | 2 | |

| Max. positioning speed | 300 mm/min | |

| Head spindle | 4000 U/min | |

| Travel X/Z | 50 mm/145 mm (expandable) | |

| Accuracy | 0.05 mm | |

| 3-Jaw-Chuck | Clamping capacity 1.8 - 56 mm inside, 12 - 65 mm outside |

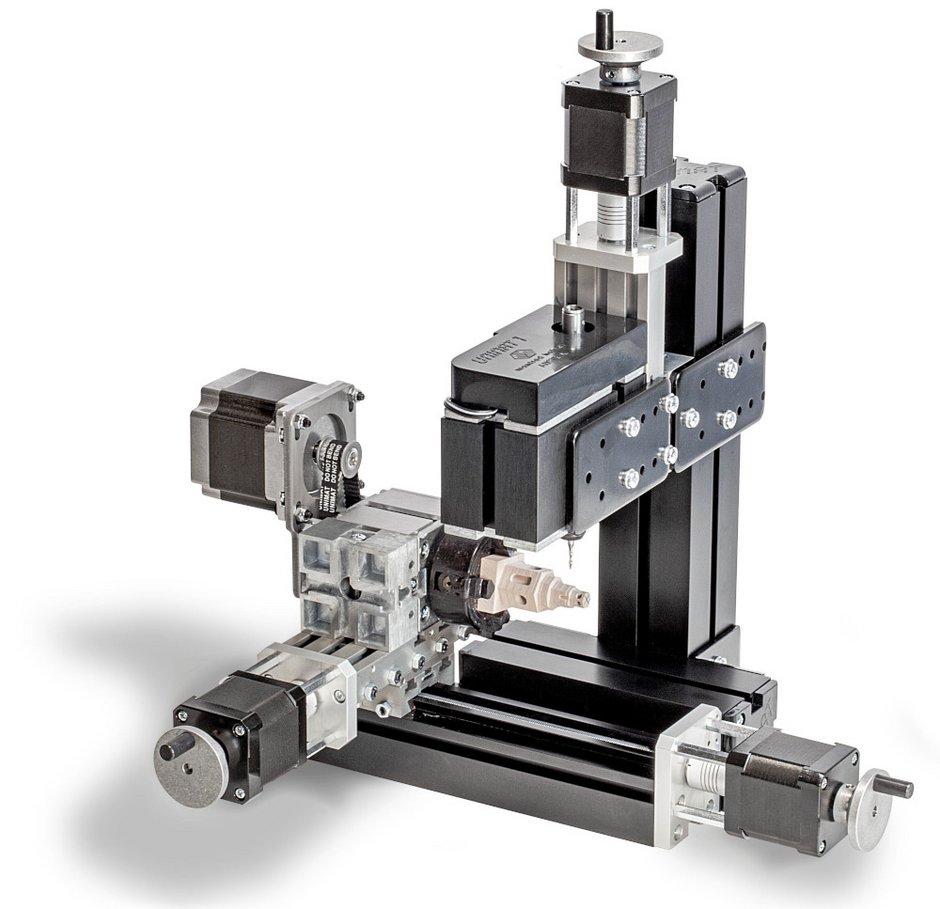

UNIMAT CNC Complete Set

UNI-CNC-SET

Incl. all parts for the UNIMAT-CNC machine variants UNI-DREH, UNI-FRAES3 and UNI-FRAES4, plus cross plate for bigger parts.

| Number of CNC axes | 4 |

| Drive | Steppers, 2 A, 1.8° |

| Max. positioning speed | 300 mm/min |

| Travels Z/Y | 50 mm (expandable)/50 mm |

| Travel X-axis | 145 mm (expandable) |

| Increment Rotation Axis | (360°/3200)*0.5 = 0.05625° |

| Accuracy | 0.07 mm |

| Head Spindle | 4000 rpm, with 1/8" collet |

| Chuck | 3-jaw chuck metal, 4-jaw chuck plastic |

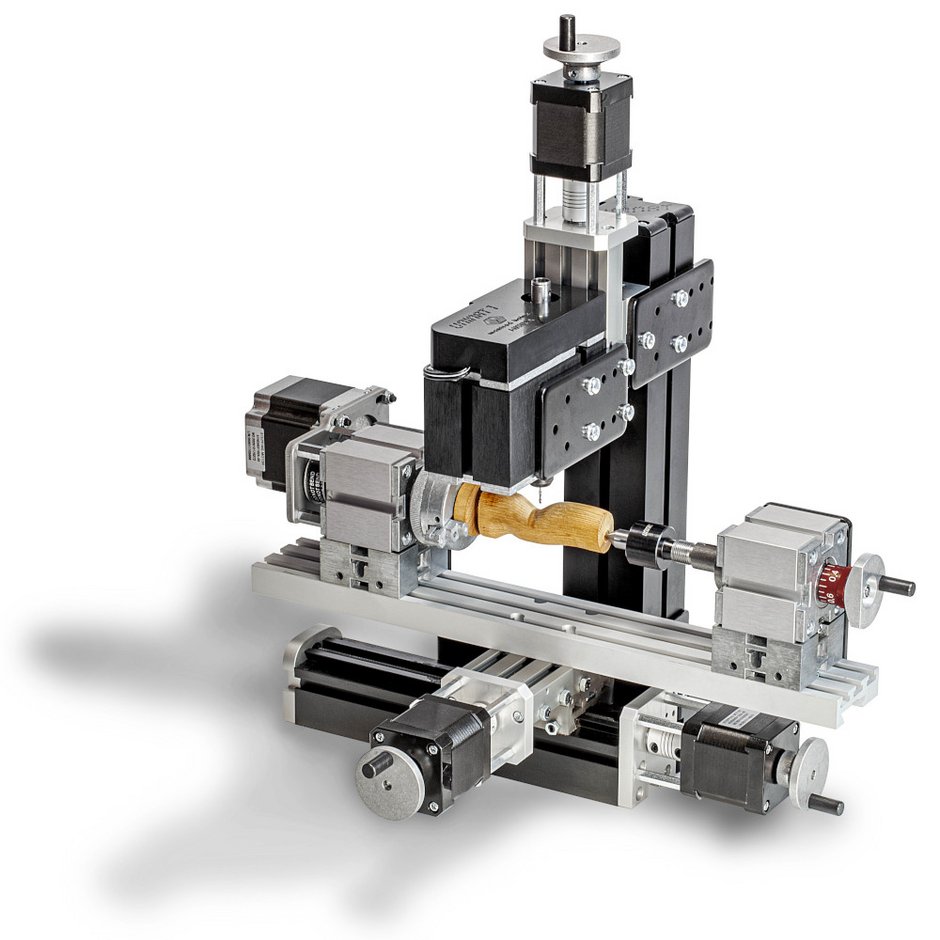

Vertical mill UNI-FRAES3EXT

Same as UNI-FRAES3 but 80mm, Y-, Z-travel and controlled milling spindle (164420 CNC)

Technical Data:

| Number of CNC axes | 3 |

| Drive | Steppers, 2 A, 1,8° |

| Max. Positioning speed | 300 mm/min |

| Travels Z/Y | 80 mm / 80 mm |

| Travel X-axis | 145 mm (expandable) |

| Increment rotation axis | (360°/3200)*0,5 = 0,05625° |

| Accuracy | 0,07 mm |

| Speed of head spindle up to | 15 000 rpm, with 1/8" collet |

Controller TCTControl

TCTCONT4

Required for controlling the UNIMAT CNC machines

The pre-installed software allows for loading, manipulating and processing of ISO standard g-code files (RS-274). It also offers an editable tool table and tool path simulation. in addition to the manual also a training book for introduction to CNC and g-code programming is included.

| Software and Drivers | Win (7, 8, 10) OSX (getestet bis OSX 10.15.x), Linux |

| Connectivity | USB, Ethernet, WIFI (optional) |

| Axes controllable | 4 (upgradeable to 6) |

| furhter IOs: | 6x input for (limit/end) switches, 1x E-stop, 2x relays, 0-10V control signal |

| Micro steps | 16 |

| Board | 1GHz CPU, 512MB DDR3 RAM, 4GB storage |

| Power supply | External, 110-240 V, 24 V, 5 A |

More configurations

UNIMAT CNC 4-Axis-Mill with speed controlled Spindle

UNI-FRAES4-SC

| Number of CNC axes | 4 |

| Drive | Steppers, 2 A, 1.8° |

| Max. positioning speed | 300 mm/min |

| Travels Z/Y | 80 mm / 50 mm |

| Travel X-axis | 145 mm (expandable) |

| Increment Rotation Axis | (360°/3200)*0.5 = 0.05625° |

| Accuracy | 0.07 mm |

| Head Spindle | up to 15,000 rpm, with 1/8" collet |

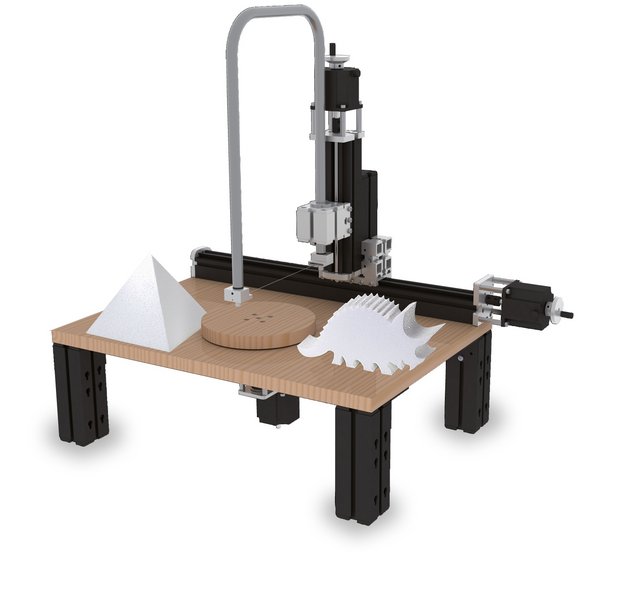

UNIMAT CNC Hot Wire Cutter

UNI-CUT-3D

| Number of CNC axes | 3 |

| Drive | Steppers, 2 A, 1,8° |

| Max. positioning speed | 300 mm/min |

| Travel X/Y | 240 mm/145 mm |

| Size Rotary Table | ø 260 mm |

| Increment Rotary Table | (360°/3200)*0.5 = 0.05625° |

| Cutting bow | width 170 mm, height 350 mm |

| Cutting transformator | continuously adjustable, 600 - 850° Celsius |

| Accuracy | 0.1 mm |

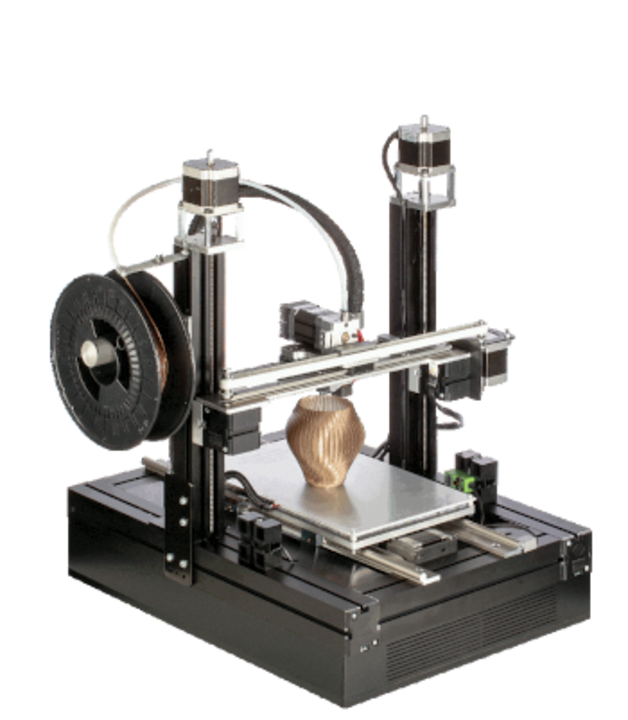

Unimat 3D-Printer

UNI-PRINT-3D

• Filament quick change, low maintenance, adjustable guideways

• Full metal frame and sturdy construction

• For all common filaments: PLA, ABS, Nylon, Laybrick etc.

• Open Source Software: Machinekit & cross platform user interface for Windows, OSX, Linux, Android

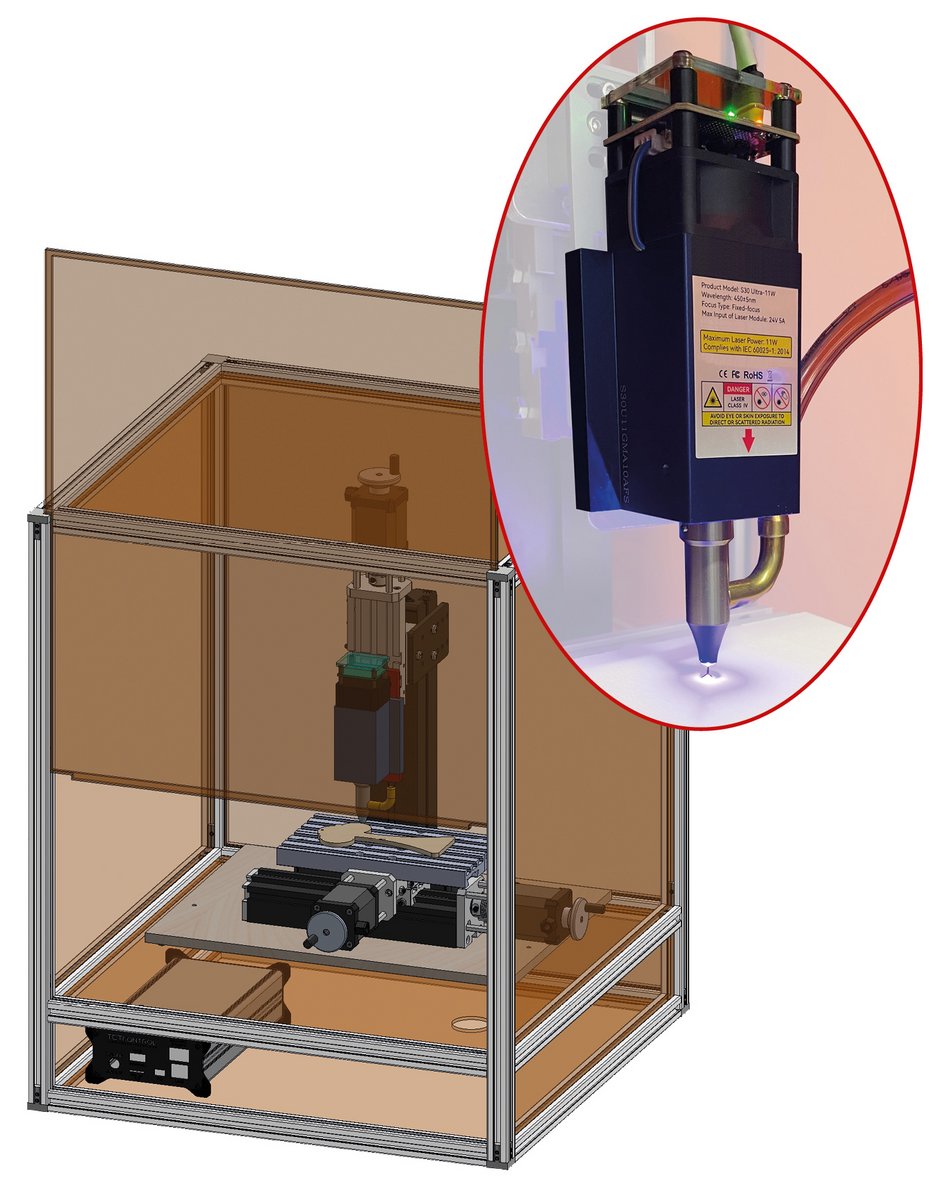

Laser-Module CNC with safety enclosure

UNI-Laser-S

The UNIMAT CNC 3-axis vertical milling machine including laser module [164510] (instead of milling motor) and UNIMAT CNC enclosure [164520].

- Including milling table plates [164520]

- TCT Control included

The laser is compatible with all variants of the UNIMAT CNC vertical milling machines (3- and 4 axes)

Laser Power: 11 W

Wavelength: 450nm

Focus type: fixed focus

Input: 24V/ 5A

Machinable materials:

| Cutting | Engraving |

|---|---|

| wood cloth acrylic various plastic carton | wood stainless steel leather acrylic ceramics various plastic carton anodized aluminium |

CNC-Upgrade Set

160200CNC4

Customers who already own a UNIMAT MetalLine Set (160200) or UNIMAT PowerLine Set (160300) can easily upgrade to CNC functionality.

Supports up to 4 CNC axes

With the included CNC rotary unit, the following machine configurations can be created:

- CNC Lathe

- Vertical or Horizontal Milling Machine (3-Axis)

- Vertical Milling Machine with Rotary Unit (4-Axis)

Included in the upgrade set:

- 1× CNC Longitudinal Slide

- 2× CNC Cross Slides

- 1× CNC Rotary Table

- All axes powered by 2A stepper motors

- TCTControl – Control electronics with integrated motion controller

- Pre-installed CNC software, capable of controlling up to 4 axes

- Training Book – Introduction to CNC and G-code programming

This upgrade makes your UNIMAT system ready for precise, automated, and repeatable machining – ideal for prototyping, education, and advanced hobby use.