Unimat MetalLine

160200

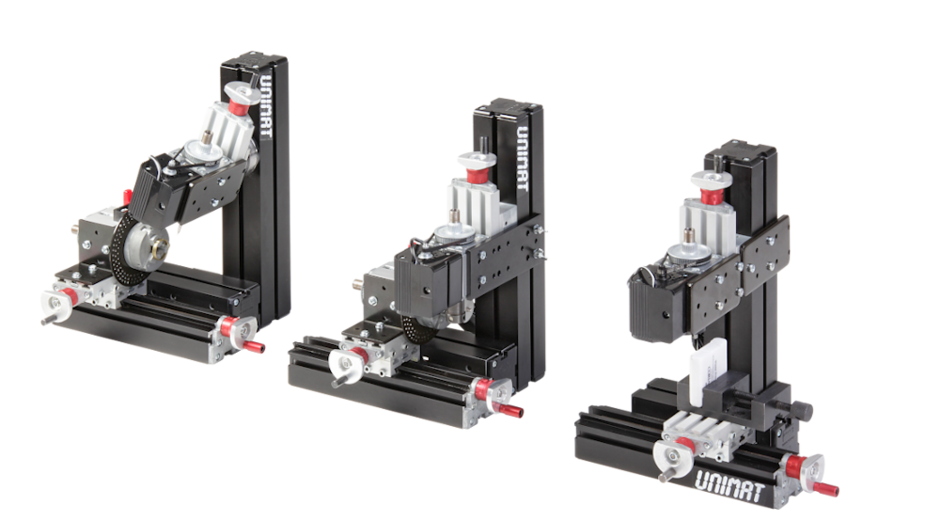

Precision in Modular Design

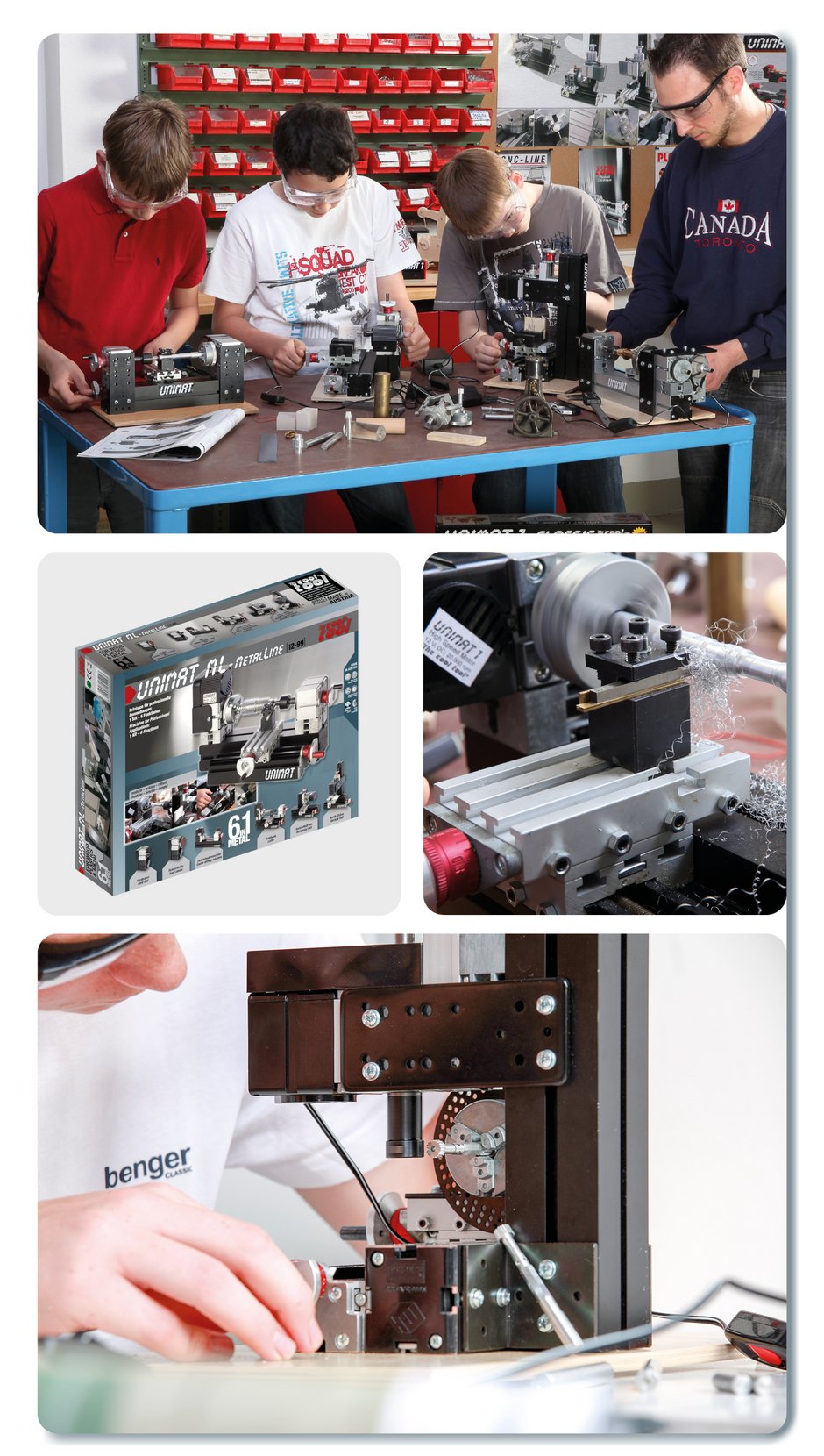

The UNIMAT MetalLine is the most powerful system within the UNIMAT series – designed for the highest demands in model building, prototype development, and even commercial applications.

It impresses with precision-engineered components, modular flexibility, and a compact design that enables professional results in the smallest of spaces.

⚙️ High-Quality Manufacturing

All structural components – including slides, intermediate shafts, tailstocks, and spacer blocks – are made of metal on state-of-the-art CNC machines.

The result: high dimensional accuracy, stability, and repeatable precision – ideal for users who value fine detail and professional quality.

The precisely matched parts ensure maximum accuracy in every machine configuration – from lathe to milling unit.

🔧 Technical Highlights at a Glance

- Modular design for maximum versatility

- Easy to use – perfect for school, workshop, or home studio

- High stability and precision thanks to CNC-machined metal parts

- Minimal tolerances through precision bearing seats

- Dust-protected industrial ball bearings for excellent concentricity

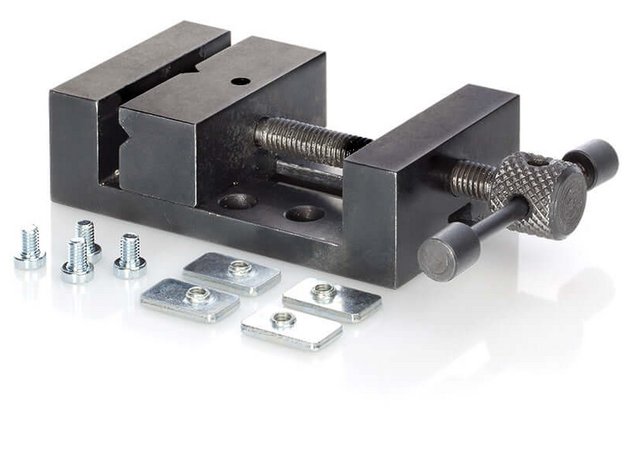

- Adjustable dovetail guides for zero-play motion

- Plan-milled and ground profiles – precisely aligned

- Torsion-resistant construction due to reinforced wall thicknesses

- Quill feed – precisely adjustable with metal handwheels, 0.05 mm scale, and adjustable vernier

✅ For Those Who Value Precision

Whether in advanced model building, design, or small-scale production,

UNIMAT MetalLine stands for quality, modularity, and technical precision.

The Functions

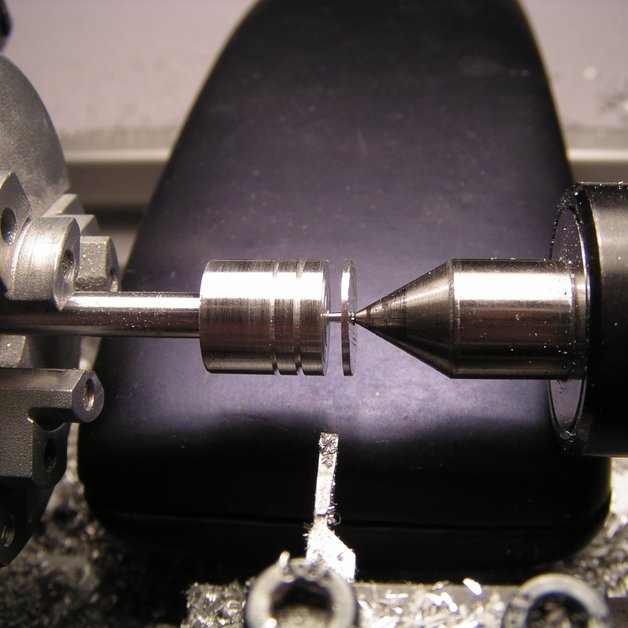

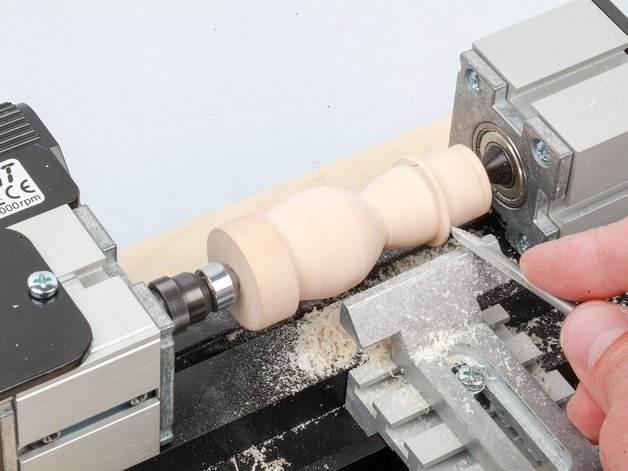

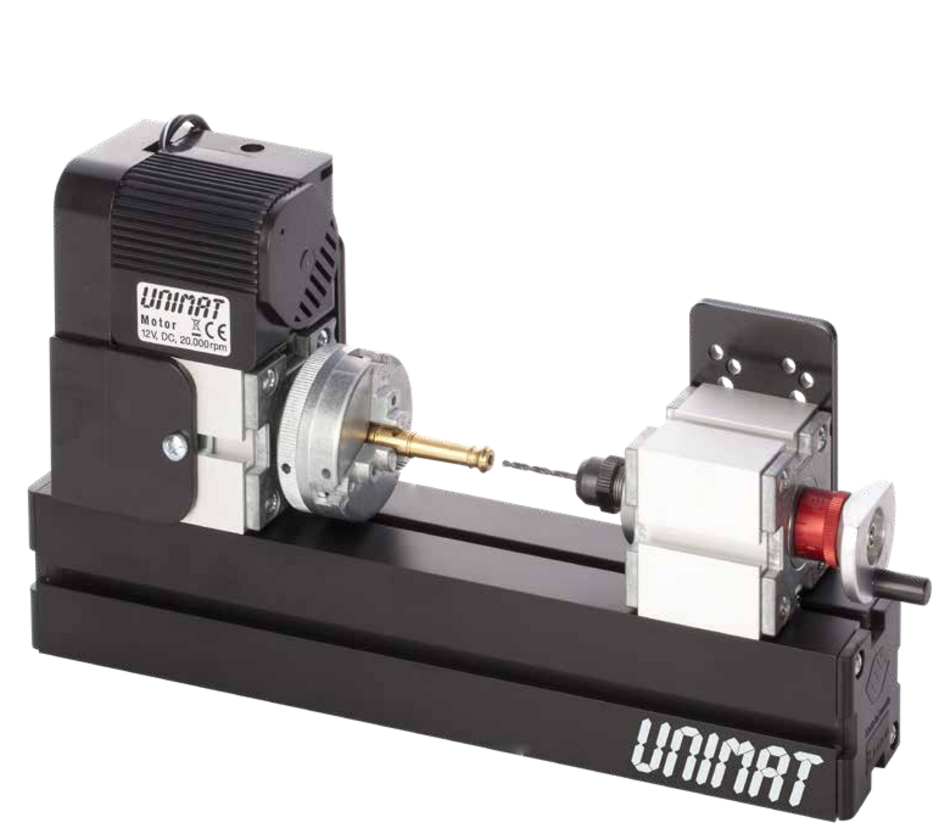

Lathe

With distance between centers of 90 mm (optionally expandable), center height of 50 mm and equipped with a two position tool post aluminum, brass, copper and other materials can be processed precisely. With the 3-jaw chuck work pieces with ø up to 56 mm (inside) and 65 mm (outside) can be clamped.

Travel: Z-axis 145 mm, X-axis 32 mm

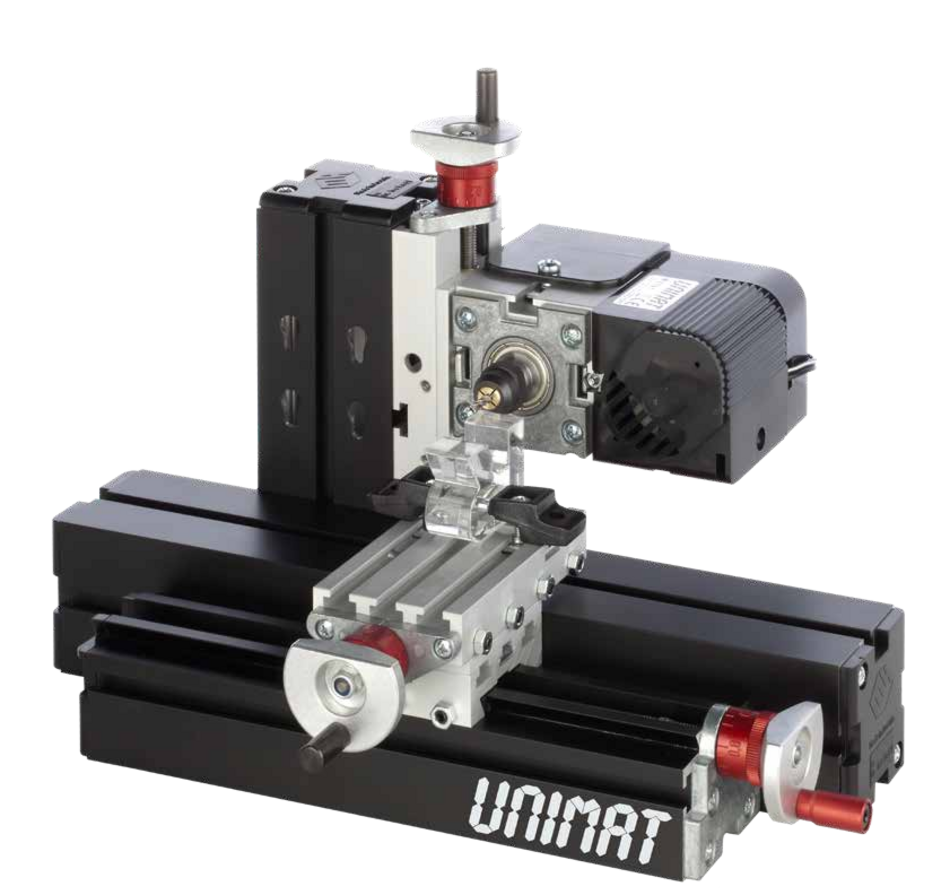

Horizontal mill

Using 3 slides allows for a wide range of milling tasks on different planes. Travel: X-axis 145 mm, Y- and Z-axis 32 mm (optionally expandable). Collets with a clamping range from 1 to 6 mm.

Center Drilling

With the precise collets, tool bits from 1 to 6 mm can be inserted into the head-spindle. The tailstock quill allows for a precise travel of 30 mm. The hand wheel with 0.05 mm scale guarantees perfect drilling results and exact depth-control.

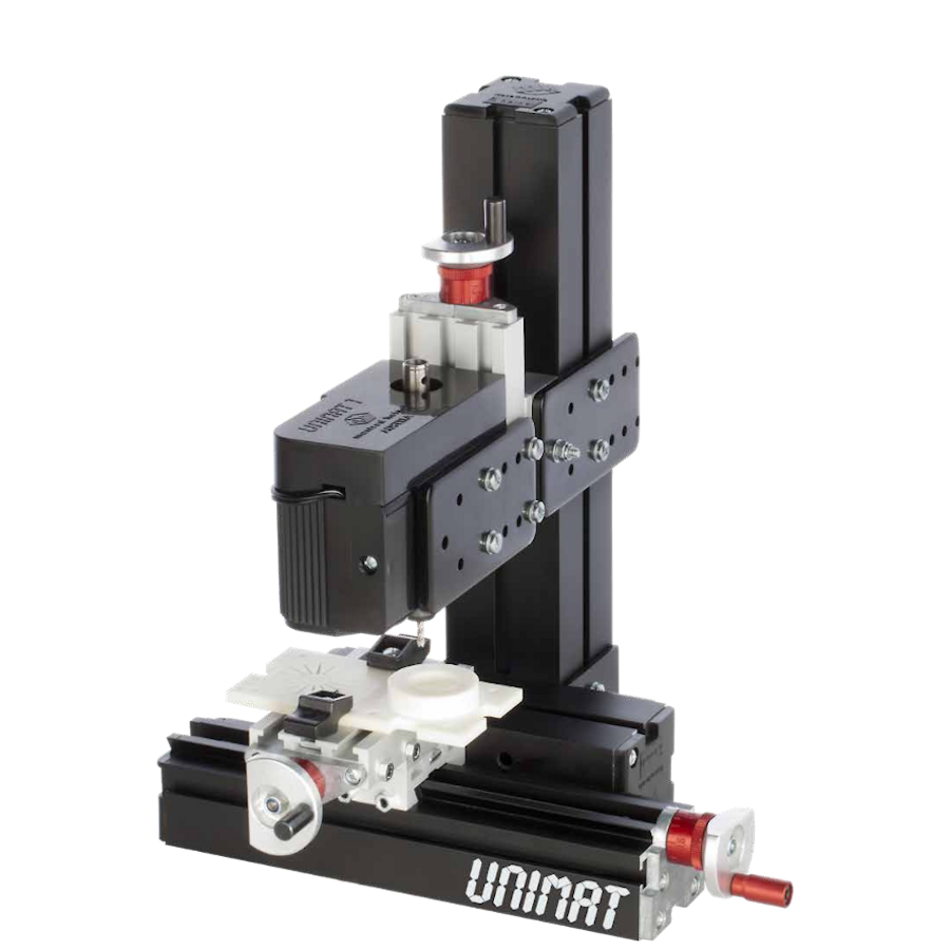

Drill Press / Vertical Mill

Two slides are used for the set-up of the cross table, the third slide is used for the Z-axis. With the hand wheels, holes can be drilled at exact positions and with exact depth.

Travel X-axis 145 mm, Y- and Z-axis 32 mm. Collets with a clamping range from 1 to 6 mm.

Handheld Drill / Sander

Handheld Drill: For drilling and milling bits with shank diameters from 1 to 6 mm.

Handheld Sander: With a 50 mm sanding disk.

Technical Data

| Motor | 20.000 rpm, 12 VDC |

| Headstock | M12x1, 8 mm hole through spindle |

| Gear ration | 1:5 (4000 rpm) |

| Slides (Travels) | 2 cross slides (30 mm), 1 long slide (40 mm), screw pitch 1 mm |

| Tailstock | M12x1, 30 mm quill travel |

| 3-Jaw-Chuck | Clamping capacity 1.8-56 mm inside, 12-65 mm outside |

| Adaptor | 110-240V/50-60Hz,14V DC, 2A |

Contents Unimat ML

160200

Overview of Equipment – Machine Components and Accessories

- Machine beds: 140 mm and 271 mm

- Longitudinal slide: 200 mm

- 2× Cross slides: each 90 mm

- Tailstock

- Metal spacer blocks

- Metal 3-jaw chuck

- Steel faceplate

- Precision live centers

- Intermediate gear unit (for variable drive ratios)

- 12 V motor

- 14 V safety transformer

- Mounting plates and brackets

Upgrade Technics

160200EDU2

Expansion Set for UNIMAT ML (Art. No. 160200)

This expansion package builds on the UNIMAT ML basic set and enables the setup of a second machine or the realization of special machine configurations. Included:

- 1× Intermediate gear unit

- 1× Motor

- Rotary table

- Indexing head

- Gear milling head

- Face milling head

- 5-piece turning tool set

- 4-piece milling tool set

- 330 mm machine bed

- 2 U66 connectors

These components allow for the assembly of the following special machines:

- 5-axis milling machine

- Gear milling machine

- Face milling machine

Application examples for special machines:

- Manufacturing gears and pinions

- Milling flat workpieces or housing parts

- Multi-sided machining of complex components through simultaneous axis movement

Upgrade Power

160200EDU3

Expansion Set for UNIMAT ML (Art. No. 160200) – More Power & Versatility for Demanding Applications

This powerful expansion set is ideal for private users and industrial applications that require greater force and stability when working with larger workpieces. Based on the UNIMAT ML basic system, it enables the setup of a second machine or the implementation of specialized machine configurations.

Included Components:

- Power motor for increased performance reserves

- Reduction gearbox for optimized torque

- Safety transformer with distributor

- Circular saw with saw blade

- Precision milling fence

- Profile milling tool set

- Professional turning setup

- 460 mm machine bed

- 2 U66 connectors

- ML jigsaw with adjustable stroke

Enables the setup of special machines such as:

- Circular saw

- Power jigsaw

- Router

- Power milling machine

- Professional lathe

This set offers a powerful extension for professional applications where precision, modularity, and machine versatility are essential.

Upgrade Your MetalLine to a Full CNC Machine

This upgrade set is designed for users who already own the UNIMAT MetalLine and wish to expand their system with CNC functionality for up to four axes.

Possible Machine Configurations:

- CNC Lathe

- Vertical or horizontal milling machine with 3 axes

- Vertical milling machine with additional rotary axis (4-axis machining)

Set Contents:

- 2 CNC cross slides

- 1 CNC longitudinal slide

- CNC rotary table with high-precision indexing head

- 2A stepper motors for all axes

- TCTControl – control electronics with integrated motion controller

- Pre-installed CNC software for easy setup

- Introductory materials for CNC and G-code programming

With this set, you can transform your UNIMAT MetalLine into a professional-grade automated system – ideal for precise machining, repeatability, and efficient project execution in hobby work, prototyping, or industry.