Differential construction

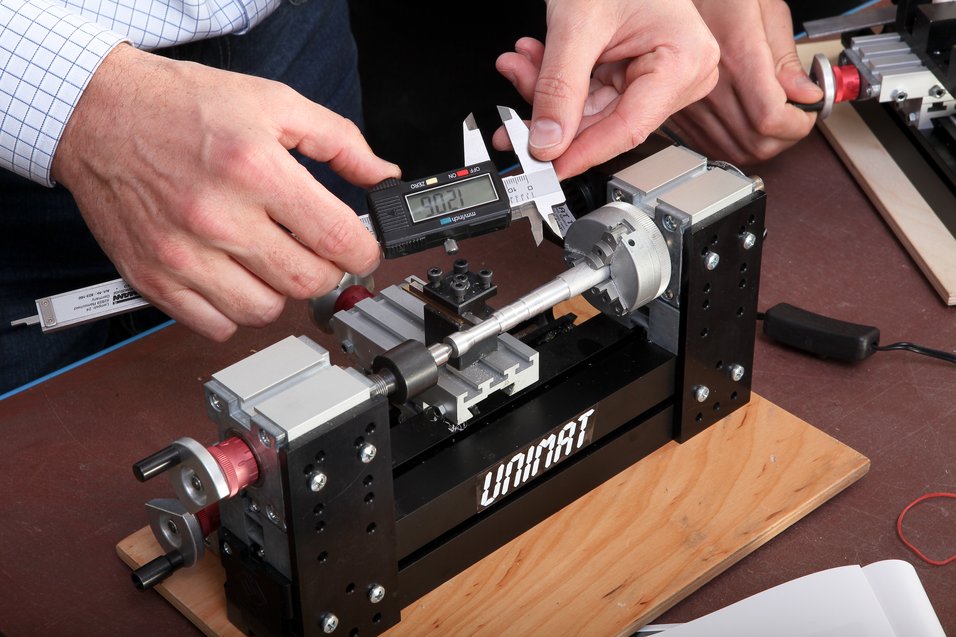

With the UNIMAT gear milling machine, it is possible to produce differentials and gears.

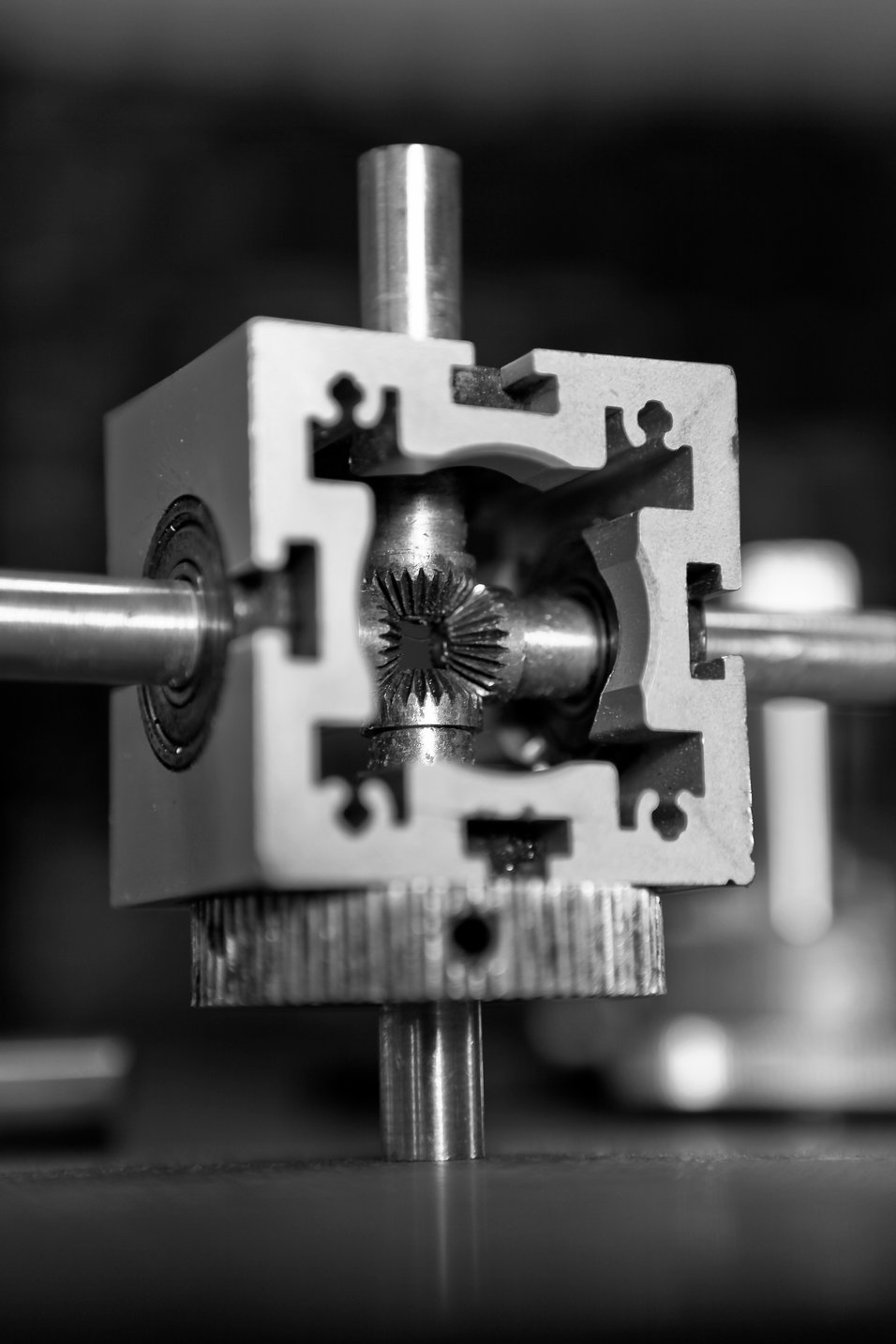

The goal of this project was to mill your own bevel gear wheels which later on can run in a box. For this box, an old countershaft is used.

Through the modularity of the UNIMAT System, single parts can also be used for models.

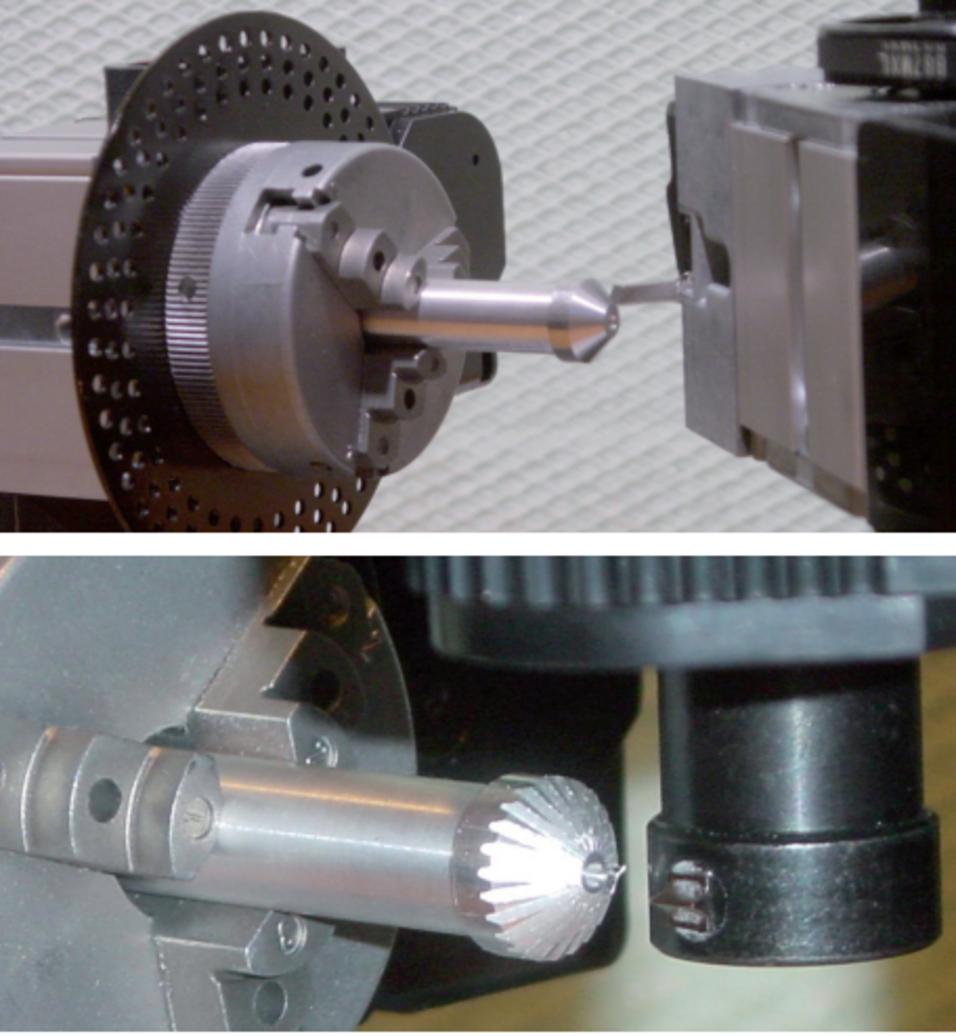

The angle of the taper is 45° degrees. When then milling smaller angels only intermediate pieces (between long-slide and machine bed) have to be removed.

In this project for 24 teeth, take the 48-divide of the dividing attachement and just use every 2nd whole. The best depth for milling turned out to be 0.95 mm.