Here you can find answers to frequently asked questions!

If your question has not been answered please contact our service-team under info@thecooltool.com for help.

General Questions

- PLAYmake 4in1 is recommended for 5 years and up.

- UNIMAT 1 Basic starting at 8 years. If kids are advised by their parents they can start earlier.

- UNIMAT 1 Classic starting at 12 years. Creative kids and craftsmen, who have expierence with the UNIMAT 1 Basic can start earlier.

- UNIMAT MetalLine starting at 12 years.

- UNIMAT PowerLine starting at 15 years.

- UNIMAT CNC starting at 15 years.

- Jig-Saw: plywood up to 12mm, solid wood up to 8mm

- Lathe:

- the every kind of wood

- fiber-free plastics

- soft and non-ferrous metal up to the temper of brass

- Turning Lathe: basically all kinds of wood are turnable, above all short grained woods as beech and fruit woods turn out beautiful. For the beginner we recommend lime wood, because it is relatively soft and has short grains which results in a beautiful surface. Even soft metals can be worked freehanded.

- UNIMAT 1 Basic: Precision depends on the users skills. All machines are worked by free hand.

- UNIMAT 1 Classic: Precision about 0,5mm, hand-wheel graduation is 0,1mm.

- UNIMAT MetalLine: With the high precision parts of MetalLine tolerances from under 0,1mm can be achieved. The hand-wheel graduation is 0,05mm.

For our UNIMAT products we offer 5 years warranty. Not included are wearing parts.

Examples for warranty parts: motor, transformator, etc. / Examples for wearing parts: jig saw blades, drive belts, sanding paper etc.

Our UNIMAT CNC and Styro-Cut 3D products have 2 years of warranty

The lift of the saw blade and so the cut movement of the teeth is only approx. 3mm. The skin is capable to move this short distance and won't get hurt. A cut into the material happens only when the materials are rigid, like wood, plastics or metals.

Spare parts can be bought through your dealer or if not available directly through us. Contact

UNIMAT 1 Basic and Classic

With our UNIMAT machines we do not recommend working with steel.

Actually PLAYmake is rather a toy with a 12V drive, whereas UNIMAT1 BASIC represents a real machine tool.

UNIMAT1 BASIC originally was developed for model construction, but is also best suited for children. Strong 12V motor, but still child friendly. Run by a 12V power supply, already included in the kit.

The primary structure of UNIMAT1 consists of aluminium profiles, while PLAYmake is made of plastic. Through upgrade sets UNIMAT1 is upgradeable indefinitely, while PLAYmake is limited to its 4 applications woodturning lathe, saw, sanding and drilling machine.

Also PLAYmake is a fully functional machine tool, however sense of achievement can only be promised when processing soft wood.

UNIMAT1 BASIC is ideal to introduce children into the world of machine tools because of its multifunctionality and the child friendly use. The machines have the same features as big industrial machines, the only differences are their size and the 12V drive.

The main area of use for the BASIC kit is wood working. Especially for woodturning and fretsaw models, where the design is done freehand, you will have much pleasure with UNIMAT1 BASIC.

For model-making professionals who also make functional models we recommend the UNIMAT1 CLASSIC kit. The CLASSIC kit contains all the components of the BASIC kit and much more. So e.g. the slides and the means of clamping, in order to fix the workpiece (e.g. the axis of an RC-car) and the required tool(e.g. lathe tool) at the most accurate position and at any random angle.

For additional machine variations, the CLASSIC kit contains the components necessary for building-up to a stationary drilling machine, a metal turning machine, and a horizontal and vertical mill.

In brief, for creative freehand working of wood and plastic we recommend the BASIC kit, for metalworking, and everywhere where it depends on precision, the UNIMAT1 CLASSIC is the kit of your choice.

By accessories optionally numerous further machine tools can be constructed. The hobby mechanical engineer is offered all possibilities by the modular system, to realize his technical dreams and ideas. The operating gear cutter still is nothing special, try to fiddle about with a spiral milling machine.... Everything conceivable is possible. To the interested our extensive supporting documents offer the equipment for starting into the world of mechanical engineering.

The UNIMAT MetalLine has a focus on high precision working, especially designed for metal working. The functions are similiar to those of the UNIMAT Classic kit, but more precise and higher quality parts are used for model making and metal working. To use the MetalLine for wood working we have a special upgrade set (162130).

The PowerLine is no individual set like the UNIMAT Basic- or Classic kit. It is an expansion for the UNIMAT MetalLine. The stronger motor of this set makes working with new machines like a circular saw possible. The applications are not child-safe anymore.

More information you can find here UNIMAT manual

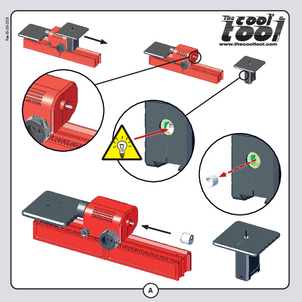

Here you find help for the UNIMAT jig saw:

- The new jig saw blade can not be fixed or easily slips from the fixation? Control if the old saw blade was properly removed and there is no dust or wood in the jig saw fixation. UNIMAT manual page 10 + 11

- The jig saw blade can not be fixed with the screw or does not fit correctly? Please control if the screw works properly. If necessary please change the metal ring and the screw - UNIMAT manual page 10 + 11

- The motor is turning but the jig saw doesn´t move? Please control if the exzenter is completely connected with the jig saw - UNIMAT manual page 10 + 11

The following tipps will help you to use the jig saw properly

- The wood vibrates with the jig saw blade and therefore can not be sawed properly -> Always press the wood on the jig saw table while sawing, this prevents the wood from vibrating and provides a clean cut Manual UNIMAT 1 Basic page 10+11

- The jig saw blade breaks while sawing circles or curves -> Press the wood in the direction of the arrow, marked on the jig saw table, while turning the wood around the jig saw blade. The jig saw blade, for safety reasons, can only cut in one direction, if too much pressure is pushed from the side it bends and can break.

These following tipps will help you to use the wood lathe correctly:

- The work pieces stop spinning easily, but the motor continues turning ->

- Please check if the drive center (this part fixes the work piece onto the machine) is driven into the wood correctly. Should the wood not be driven in properly it can spin while under pressure.

- Check if the collet holder (U48) is screwed on firmly - this prevents it from spinning.

- The work piece and the motor stop spinning.

- Please check if you are holding the gauge correctly. -> Do not apply to much pressure on the gauge, this can prevent the wood from spinning. The blade is sharp enough to cut the wood with little pressure applied.

- The work piece wobbles (does not spin in a perfect circle)

- With the center finder (enclosed in the UNIMAT kits) you can find the exact center of the work piece, but wood is a natural product so small tolerances and imbalances are normal. For precise and smooth working we recommend to take of the top wood layer of the work piece (around 1-2 mm) before starting with the actual model making.

PLAYmake 4in1 Workshop

More information you can find in the PLAYmake manual

These are some tipps for the PLAYmake jig saw:

- The new jig saw blade can not be fixed or slips out of the fixation? - Control if the old saw blade was properly removed and there is no dust or wood in the jig saw fixation PLAYmake manual page 40

- The jig saw blade can not be screwed in? Please control if the screw works properly. If necessary please change the metal ring and the screw PLAYmake manual page 25+40

- The motor is turning but the jig saw doesn´t move? Please control if the exzenter is connected properly with the jig saw - PLAYmake manual page 27

The following tipps will help you to use the jig saw properly:

- The wood vibrates with the jig saw blade and therefore can not be sawed properly -> Always press the wood on the jig saw table while sawing, this prevents the wood from vibrating and provides a clean cut.

- The jig saw blade breaks while sawing circles or curves -> Press the wood in the direction of the arrow, marked on the jig saw table, while turning the wood around the jig saw blade. The jig saw blade, for safety reasons, can only cut in one direction, if too much pressure is pushed from the side it bends and can break.

- The work piece stops spinning easily, but the motor continues turning ->

- Please check if the drive center (this part fixes the work piece onto the machine) is driven into the wood correctly. Should the wood not be driven in properly it can spin while under pressure.

- The work piece and the motor stop spinning.PLAYmake manual page 8+17

- Please check if you are holding the gauge correctly -> Do not apply to much pressure on the gauge, this can prevent the wood from spinning. The blade is sharp enough to cut the wood with little pressure applied.

- The work piece wobbles (does not spin in a perfect circle)

- With the center finder (enclosed in the UNIMAT kits) you can find the exact center of the work piece, but wood is a natural product so small tolerances and imbalances are normal. For precise and smooth working we recommend to take of the top wood layer of the work piece (around 1-2 mm) before starting with the actual model making.

The PLAYmake 4in1 kit has a special designed machine bed, which enables it to be connected to commong big building plates - PLAYmake manual page 29

If you need more fixiaton you can use building blocks to further stabilize the PLAYmake.

Alternatively you can use the 4 screws which are included in the kit and use them to screw it onto a wooden base plate. PLAYmake manual page 6

UNIMAT MetalLine + PowerLine

For all PowerLine applications we recommend our variable power adaptor 12V or a second standard transformator with a 12V connector

Yes, the MetalLine can be upgraded with CNC-slides and controller (with software installed). Most machine variants can be CNC controlled alternatively. More information here UNIMAT CNC

No, at the moment we do not have an application for cutting threads.

Yes, the speed of the machine can be adjusted. Either through reduction or a variable power adaptor 12V.

For bigger work pieces we recommend using a Powermotor (164320) and Reduction set f. PowerLine Motor(164325). For normal diameters you can use the variable power adaptor 12V(161410) to adjust the rotation speed.

UNIMAT CNC

The computerized manufacturing of a model starts with designing it on a PC. For this purpose a wide range of CAD (Computer Aided Design) applications are available on the market.

In the next step, the design file is opened with the CAM (Computer Aided Manufacturing) oftware. The CAM application generates the tool paths based on your entered and defined processing parameters. These paths, as well as certain other machine commands, are converted into G-Code (normed programming language of numerical control). Most CAM applications can export such machine code in compliance with the RS274D standard (DIN 66025). G-Code for simple geometrical forms can also be compiled manually.

In the third and final step this code has to be imported into a CNC (Computerized Numerical Control) application. Line-by-line, the commands are converted into processing signals for the drive motors. The machine travels according to these directions and the work piece is processed.

ISO standard G-Code files (RS-274, DIN 66025) with extension .ngc can be loaded.

See explanation in reading sample CNC Handbook page 5.

2D and 2½D (layer milling, engraving): For simple graphics and layouts free software Inkscape can be used (reading sample CNC Handbook page 10)

3D: For 3D-Designs and solid models CAD and CAM application are used - eg. Autodesk Fusion 360 or DeskProto. See the tutorials Postprocessors for Fusion 360.

(When using other CAM software please make sure suitable posts for LinuxCNC are available.)

Writing and editing gcode is possible in almost any text editor. If you don't have any, check out Notepad++

Yes, sample files and exercises for the machine configurations can be found on the controller and loaded after start.

Windows7 and 10: Connection via USB or ethernet. (Wi-Fi optional).

Linux (Ubuntu, etc): Connection via USB or ethernet. (Wi-Fi optional).

OSX: Connection via ethernet (Wi-Fi optional). USB connection only with older versions of OSX .

The FAT-partition containing client and other documentation will be mounted under any OS (including current versions of OSX).

In case driver installation fails, alternatively NDIS-drivers supplied by Microsoft can be installed in the device manager.

Yes, this is basically possible. However, setup must be carried out by you or your system administrator.

Yes, for TCTControl we do offer an emergency stop and relay module, that also allows for switching the Unimat CNC standard motor on and off from software.

See accessory 164425CNC E-stop/Relay module.

Yes, for the CNC 3 and 4-axis mill there is a speed controlled spindle motor available.

See accessory Milling and Engraving Spindle 164420CNC.

No, we do not offer such at the moment.

Please contact us! We shall be happy to send the download link for the latest version of the client for 32-bit.

TCTControl: Perform an online-update. In case the update aborts, just restart it until it finishes - all files will be restored.

SandyBox: Please contact us (online update is not available).

For USB connection: PLease make sure the supplied driver has been installed successfully (see question about driver installation).

For LAN connection: Has the IP adress of the contrller been set correctly (default 192.168.0.3)?